No Products in the Cart

This Kiln is Made-To-Order only with a lead Time of approximately 5-6 weeks.

|

Brand |

Model |

Controller |

Cone |

Temperature |

Sides |

Depth |

|

Skutt |

1627 |

Touchpad or Touchscreen |

10 |

2350° F |

16 |

27” |

|

Width |

Volume |

Weight |

Phase |

Voltage |

Watts |

Amps |

|

46” X 31" |

18.5 cu ft. |

535lbs |

3 phase |

240V or 208V |

9984W / 11520 |

66/76A |

One of the most important things you need in a large production kiln is power… and the KM1627-3 has it in spades!. An under-powered production kiln will fire slow and cause your elements to spend more time than necessary at high temperatures which can drastically reduce their useful life.

One of the most important things you need in a large production kiln is power… and the KM1627-3 has it in spades!. An under-powered production kiln will fire slow and cause your elements to spend more time than necessary at high temperatures which can drastically reduce their useful life. Time is money, and when you are in business you can’t afford to waste either one.

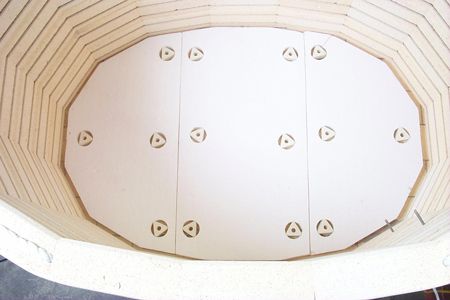

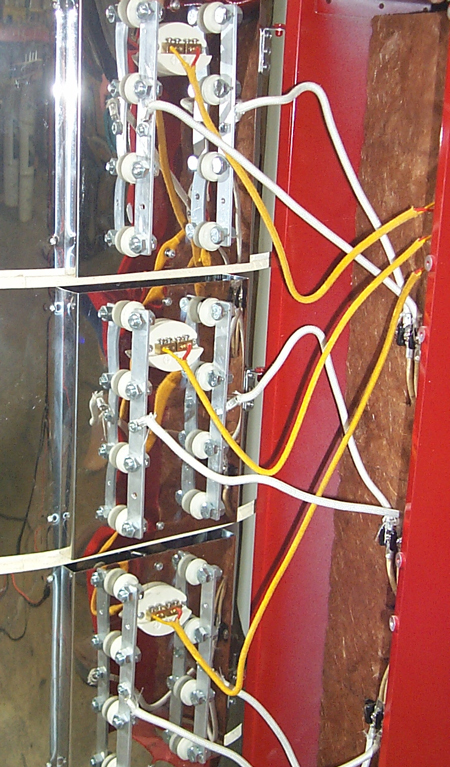

The more than 23000 watts of power is delivered by industrial grade wiring and components that can more than handle it. The elements are connected by a unique bus bar system make it very easy to replace the elements.

With a big oval lid you need to lid braces to support it. Prior to Skutt’s new lid brace design oval owners use to do what we affectionately called the lid dance. It seemed every time you released one lid brace with your free hand not holding the lid up, the other lid brace would fall back into it’s groove. Skutt’s unique design works much like an extension ladder. Just lift the lid up until the cams on each side cover the locking notch and then lower the lid

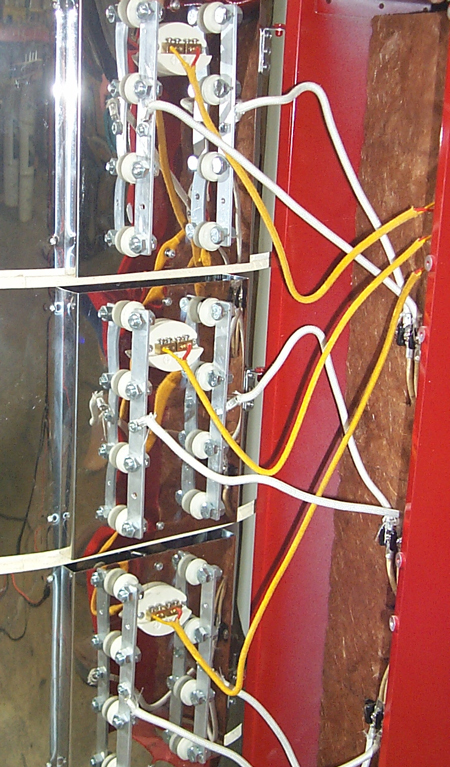

You ask anyone who has run an oval kiln for a period of time and they will tell you the most frustrating things to deal with are the lid and the slab. Big lids and slabs want to bend like a potato chip during the firing. This is caused by the surfaces on the inside of the kiln expanding greater than those on the outside. To help combat this, Skutt has done two things.The first was to replace the traditional brick lid with an Engineered fiber lid that not only resists cracking, it is also lighter. The second thing we did was to insulate the bottom slab from the heat with a fiber insert. By reducing the temperature difference between the inside and outside surfaces we were able to drastically reduce the amount of cracking.

|

Brand |

Model |

Controller |

Cone |

Temperature |

Sides |

Depth |

|

Skutt |

1627 |

Touchpad or Touchscreen |

10 |

2350° F |

16 |

27” |

|

Width |

Volume |

Weight |

Phase |

Voltage |

Watts |

Amps |

|

46” X 31" |

18.5 cu ft. |

535lbs |

3 phase |

240V or 208V |

9984W / 11520 |

66/76A |

One of the most important things you need in a large production kiln is power… and the KM1627-3 has it in spades!. An under-powered production kiln will fire slow and cause your elements to spend more time than necessary at high temperatures which can drastically reduce their useful life.

One of the most important things you need in a large production kiln is power… and the KM1627-3 has it in spades!. An under-powered production kiln will fire slow and cause your elements to spend more time than necessary at high temperatures which can drastically reduce their useful life. Time is money, and when you are in business you can’t afford to waste either one.

The more than 23000 watts of power is delivered by industrial grade wiring and components that can more than handle it. The elements are connected by a unique bus bar system make it very easy to replace the elements.

With a big oval lid you need to lid braces to support it. Prior to Skutt’s new lid brace design oval owners use to do what we affectionately called the lid dance. It seemed every time you released one lid brace with your free hand not holding the lid up, the other lid brace would fall back into it’s groove. Skutt’s unique design works much like an extension ladder. Just lift the lid up until the cams on each side cover the locking notch and then lower the lid

You ask anyone who has run an oval kiln for a period of time and they will tell you the most frustrating things to deal with are the lid and the slab. Big lids and slabs want to bend like a potato chip during the firing. This is caused by the surfaces on the inside of the kiln expanding greater than those on the outside. To help combat this, Skutt has done two things.The first was to replace the traditional brick lid with an Engineered fiber lid that not only resists cracking, it is also lighter. The second thing we did was to insulate the bottom slab from the heat with a fiber insert. By reducing the temperature difference between the inside and outside surfaces we were able to drastically reduce the amount of cracking.