No Products in the Cart

This Kiln is Made-To-Order only with a lead Time of approximately 12-16 weeks.

|

Brand |

Model |

Controller |

Cone |

Temperature |

Sides |

Depth |

|

Skutt |

818 |

Touchpad or Touchscreen |

10

|

2350° F |

8 |

18” |

|

Width |

Volume |

Weight |

Phase |

Voltage |

Watts |

Amps |

|

18” x 18" |

2.6 cu ft. |

145lbs |

1 or 3 |

240V or 208V |

6400W-5550W |

26.7 |

KilnMaster Touchscreen with Built-in WiFi

Like Your Smartphone the new KMT controller navigates with just a touch of a finger and allows us to guide you through programming with full sentences, helpful icons, and dynamic navigation.

Built-in WiFi makes it possible to download any software feature upgrades for free so it is like having a new Kiln Controller for the life of the kiln.

A Free App works in conjunction with the WiFi and allows you to monitor your kiln temperature and status from your smartphone.Think how comforting it will be not to get out of bed to be sure your kiln shutoff as expected.

The Hinged Controller allows you to move the controller up and down to an angle that is comfortable for you to program. No more getting on your hands and knees. After programming you can push it back down so it is out of your way and easy to view from across the room.

It has the Same Functions you have come to know and love from the standard KilnMaster Controller Plus More!

There are exciting New Functions that are on this controller as well.

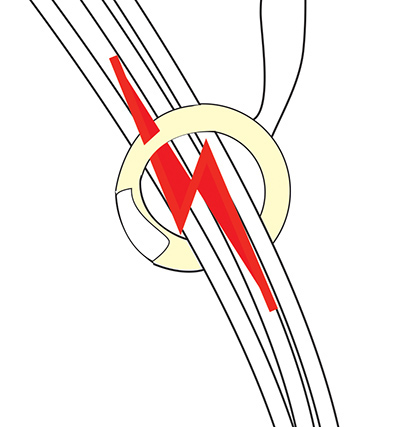

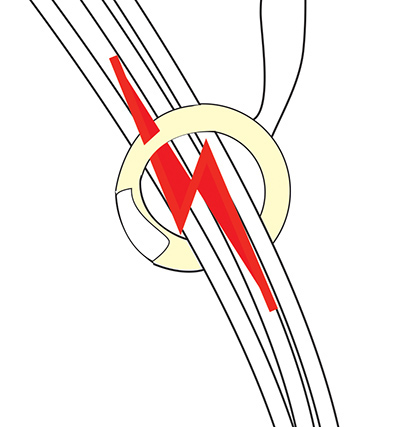

Skutt installs a Current Sensor in every KilnMaster kiln which allows you to read the amperage of each section of the kiln as well as the voltage and voltage under load.

Now with the touch of a few buttons you can give those readings over the phone to your kiln repair technician so they can troubleshoot the problem and make sure they have the correct parts when they come out for the repair, saving time and money.

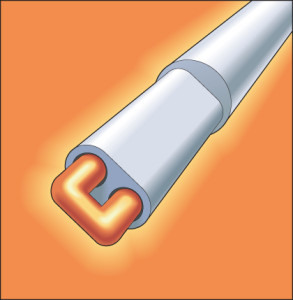

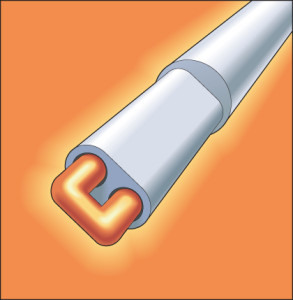

A large amount of the heat you lose in your kiln passes to through the lid and slab of your kiln. To compensate for this, Skutt directs more heat to these areas when they design the elements. The fact that we have twice the element grooves in our kilns gives us more design flexibility than some of our competitors.

A large amount of the heat you lose in your kiln passes to through the lid and slab of your kiln. To compensate for this, Skutt directs more heat to these areas when they design the elements. The fact that we have twice the element grooves in our kilns gives us more design flexibility than some of our competitors. It also gives you more loading options since it is always recommended to have at least one element radiating between each layer of shelves.

Exposed Thermocouple equals faster reaction time and higher accuracy. Easy and quick to replace and inexpensive, plus we give you an extra one when you buy your kiln.

|

Brand |

Model |

Controller |

Cone |

Temperature |

Sides |

Depth |

|

Skutt |

818 |

Touchpad or Touchscreen |

10

|

2350° F |

8 |

18” |

|

Width |

Volume |

Weight |

Phase |

Voltage |

Watts |

Amps |

|

18” x 18" |

2.6 cu ft. |

145lbs |

1 or 3 |

240V or 208V |

6400W-5550W |

26.7 |

KilnMaster Touchscreen with Built-in WiFi

Like Your Smartphone the new KMT controller navigates with just a touch of a finger and allows us to guide you through programming with full sentences, helpful icons, and dynamic navigation.

Built-in WiFi makes it possible to download any software feature upgrades for free so it is like having a new Kiln Controller for the life of the kiln.

A Free App works in conjunction with the WiFi and allows you to monitor your kiln temperature and status from your smartphone.Think how comforting it will be not to get out of bed to be sure your kiln shutoff as expected.

The Hinged Controller allows you to move the controller up and down to an angle that is comfortable for you to program. No more getting on your hands and knees. After programming you can push it back down so it is out of your way and easy to view from across the room.

It has the Same Functions you have come to know and love from the standard KilnMaster Controller Plus More!

There are exciting New Functions that are on this controller as well.

Skutt installs a Current Sensor in every KilnMaster kiln which allows you to read the amperage of each section of the kiln as well as the voltage and voltage under load.

Now with the touch of a few buttons you can give those readings over the phone to your kiln repair technician so they can troubleshoot the problem and make sure they have the correct parts when they come out for the repair, saving time and money.

A large amount of the heat you lose in your kiln passes to through the lid and slab of your kiln. To compensate for this, Skutt directs more heat to these areas when they design the elements. The fact that we have twice the element grooves in our kilns gives us more design flexibility than some of our competitors.

A large amount of the heat you lose in your kiln passes to through the lid and slab of your kiln. To compensate for this, Skutt directs more heat to these areas when they design the elements. The fact that we have twice the element grooves in our kilns gives us more design flexibility than some of our competitors. It also gives you more loading options since it is always recommended to have at least one element radiating between each layer of shelves.

Exposed Thermocouple equals faster reaction time and higher accuracy. Easy and quick to replace and inexpensive, plus we give you an extra one when you buy your kiln.